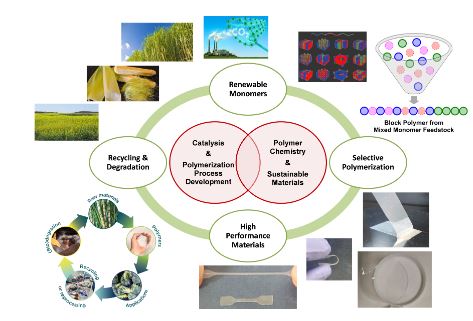

Sustainable Polymer Chemistry

A key aspect of our research is the production and properties of polymers that address sustainability concerns associated with conventional materials. Our research includes investigations of alternative raw materials, like waste carbon dioxide or biomass, as the feedstocks for polymer production; the optimization of these sustainably sourced polymers’ properties to challenge today’s materials and the broadening of end-life options to allow for recycling and/or degradation.

Avoiding Virgin Petrochemicals

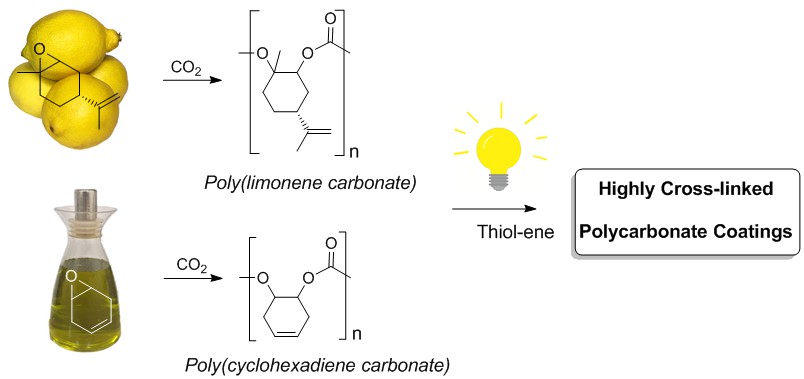

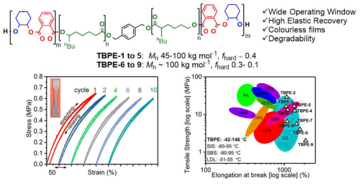

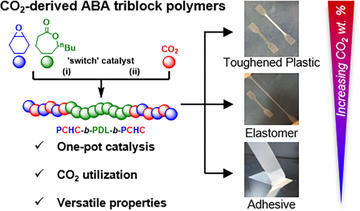

Our group investigate alternatives to virgin petrochemicals as the monomers in polymer production, for example using carbon dioxide, biomass or industrial wastes offers a means to avoid virgin petrochemicals. By using these natural, oxygenated monomers and efficient living polymerisation methods we can install regularly placed ‘break-points’ in the polymer backbone, in the form of ester/carbonate/ether bonds; these linkages facilitate end-life recycling and, in some cases, biodegradation. For lead materials, we collaborate to investigate the products’ life cycle impact assessment to qualify and, where appropriate, quantify the sustainability improvements. Some of our work involves using new monomers, such as terpene derived tricyclic anhydrides or sugar-derived lactones. However, many of the materials we investigate are already commercial products (e.g. epoxides, anhydrides, lactones and carbon dioxide) and this may be useful to accelerate change. In some cases, these monomers are sourced from petrochemicals but in future many could be bio-derived or sourced from wastes. By understanding how to selectively enchain these monomers, e.g. using switchable catalysis, we can expand the range of polymer properties without expanding the monomer pallet.

Properties and Application Potential for Sustainable Polymers

We investigate the thermal, rheological and mechanical properties of the new polymers and copolymers. Our goal is to develop polymers that show equivalent, or in some cases, better properties than conventional polymers and which can be processed using conventional methods/equipment. Recent research has included: 1) Thermoplastic elastomers which are ductile, resilient, recoverable and fully degradable; they exceed the operating temperature range and mechanical properties of styrenic copolymers. 2) Renewable and degradable polyester pressure sensitive adhesives showing performances akin to commercial tapes without requiring additives. 3) Precision carbon-dioxide linkage placement to yield fully degradable and toughened plastics. 4) Exploiting alternating hydrophilic/phobic functional substituents attached to fully degradable to allow for polymer self-assembly.

Depolymerization, Chemical Recycling and Degradation

One of the advantages of the polyester/carbonate/ether backbones is their potential to undergo catalysed chain scission or degradation reactions. We are investigating these depolymerization reactions as a means to deliver chemical recycling (degradation of polymer to monomers or pre-monomers), or, in some cases, to allow for biodegradation. For example, we recently showed the efficient depolymerization of poly(limonene carbonate) blocks to re-form limonene oxide and carbon dioxide. Overall, our work into polymer recycling involves both catalyst development (kinetics) and examination of the polymer-monomer equilibria (thermodynamics). In collaboration with partners and sponsors we are investigating degradations under a range of different conditions.