Polyester Chemistry

Our research team investigates methods to make, use and dispose of various polyesters. We are particularly focussed on the synthesis of polyesters using two different controlled polymerisations: 1) Epoxide/Anhydride Ring Opening Copolymerisation (ROCOP) and 2) Cyclic Ester Ring Opening Polymerisation (ROP). Controlled or living polymerisations are useful because they allow for predictable and correlated catalysis-polymer chemistry properties, e.g. chain length, end-group chemistry, composition or architecture. They are important in the production of more complex co- or terpolymer structures and are key to switchable polymerization catalyses. Our team also investigates the properties and application potential for these polyesters, e.g. in packaging, house-hold goods sectors, automotive components, surfactants and medicine. Investigations to improve polymer sustainability underpin all this work and tackle issues throughout the lifecycle including monomer sourcing, polymer recyclability and, ultimately, (bio)degradation.

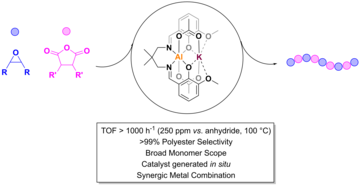

Epoxide/Anhydride ROCOP Catalysis

We have developed high activity and selectivity metal catalysts for a range of different epoxide/anhydrides, including bio-based monomers like succinic anhydride, glycerol derived epoxides, limonene oxide and terpene derived tricyclic anhydrides. Our work has included investigations of synergic dinuclear metal catalysts, using alkali/alkaline earth metals or combinations with transition metals. There are parallels with our investigations into carbon dioxide/epoxide ROCOP although the specific catalyst performances are different. Our objectives are to prepare higher performance catalysts, to understand kinetics and mechanisms and to control the catalysis to deliver the desired chain and chain end-group chemistry. We have reported some of the most active catalysts in this field and continue to explore earth-abundant, light-weight and inexpensive metals as the active sites for these catalysts.

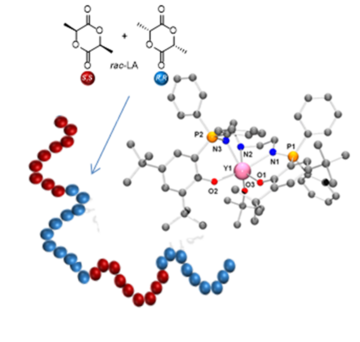

Lactide or Lactone ROP Catalysis

Polylactide (PLA) is the largest scale commercial bio-derived and biodegradable plastic: improving its properties and manufacturing efficiency remains essential. Isotactic PLA shows better thermal and mechanical resistance than other grades, our team have established catalysts that simultaneously increase rates, produce high molecular weight PLA, and show outstanding isotacticity. We have established they operate by chain end control mechanisms which means they obviate chiral additives, maintain very high rates throughout reactions and tolerate low loadings. At a molecular scale, they show dynamic conformational changes on the polymerisation timescale, especially at distal phosphorus atom substituents. We use detailed kinetic, spectroscopic, DFT (Antoine Buchard, Bath University) and structure-activity investigations to understand the performances of these catalysts. In collaboration with Paul Beer (Oxford Chemistry), we reported the first examples of conformationally dynamic molecules, rotaxane organo-catalysts which are also isoselective. In collaboration with Polly Arnold (UC Berkeley) we are investigating catalysts producing high molar mass cyclic PLA and polyesters.

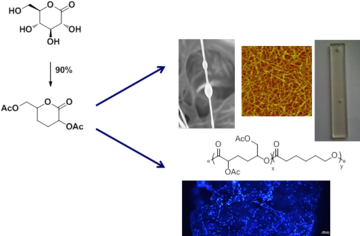

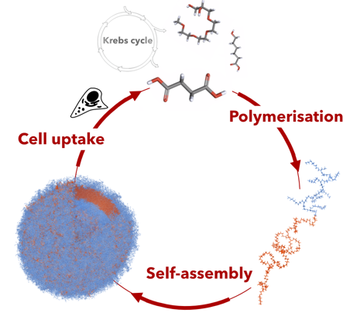

Polyester Sustainability

We investigate the properties and sustainability of these polyesters with research directed throughout their life cycles – from the sourcing of the monomers, through to improving processing and properties, through to end-life options like chemical recycling and biodegradation. Our research interests in this area include the recycling of CO2 and waste biomass into monomers. We have developed an efficient and scalable synthesis of carbohydrate lactones, starting from abundant D-glucose, which are (co)polymerised to deliver hydrophilic and degradable polyesters. In collaboration with Molly Stevens (Imperial College London), these materials were applied as matrices in tissue regeneration. In collaboration with Beppe Battaglia (UCL) we have investigated amphiphilic polyesters self-assembly to produce fully biodegradable polymersomes and established there are different cellular responses to degradation. In collaboration with Alexander Bismarck (Vienna) we have developed fully renewable composites comprising cellulose fibres and bio-renewable polymer matrices – these fully transparent materials show higher tensile strength than PLA alone. We continue to investigate how to improve the processing and properties of PLA, through production of degradable polyester additives to reduce brittleness and increase toughness. We research the options to recycle (either through re-processing or chemical recycling) these aliphatic polyesters. We seek to discover the mechanisms, theories and options to understand and predict bioplastic degradation and environmental fate.